Texas’ #1 Laser Rust Cleaning Service

Rust | Mold | Graffiti | Oil & Grease | Organic Corrosion

Alien Laser Cleaning specializes in precision laser ablation for rust, paint, and contamination removal across industrial, commercial, and restoration applications. Unlike sandblasting or chemical stripping, laser cleaning is non-contact and media-free—it selectively removes unwanted layers while protecting the base material. That means cleaner results, less waste, and faster turnaround.

Our team provides turnkey mobile services for factories, refineries, utilities, fleets, and fabrication shops, as well as restoration work for automotive, maritime, and historical assets. Typical targets include rust and mill scale, epoxy and powder coat, weld discoloration, grease and oils, smoke damage, and surface prep prior to coating or NDT.

We also design and supply laser cleaning machines (various wattages and cooling options) tailored to your workflow. From compact on-site units to higher-power systems for continuous operation, we help you evaluate ROI, safety, and training so your team ramps quickly and safely.

Why laser? You’ll reduce consumables and waste disposal, protect critical tolerances, and cut downtime—often working in-place without masking or disassembly. With Alien Laser Cleaning, you get expert operators, 10 years in the industry, proven process settings, and honest guidance on when laser is the best tool (and when it isn’t).

We Now Sell Custom Laser Cleaning Equipment

New Patent Pending Laser Cleaning Equipment!

From 300-500 Watts Pulse

1000-2000 watts Continuous Wave

Air Conditioned Laser Machines

(not to be confused with “air Cooled”)

To 1000-2000 watts Pulse Machines.

All of the above can be placed on our Crawler Kit

Rust Cleaning Sample

(2000 watts Continuous Wave)

We are now Patent Pending on our Laser Crawler System.

Laser Rust Removal Restoration and Cleaning

What is it?

One of the most important applications of laser cleaning is the removal of rust and unwanted painted substrates. Rust is a thin layer of oxidized material that can arise on the outside of a metal surface and formed by the reaction of iron and oxygen in the catalytic presence of water or air moisture. The traditional techniques to remove rust are sanding, chemical treatment, sandblasting, dry ice blasting, etc. These techniques are either very time consuming or have a big impact on the environment.

Our unique laser cleaning service allows our customers to reduce production interruptions and enhance productivity. Solving problems effectively and efficiently, helping our customers reach and exceed their goals.

20X Faster – We clean faster than using chemicals

Efficient – set-up is easy and we can start cleaning in minutes

Minimal space required – laser cleaning does not require extra space, meaning little impact on surrounding work areas

Safe – laser cleaning will not leave chemical, mechanical or thermal strain on the substrate

Mobile – the laser can easily be maneuvered providing flexibility

Clean – low noise, no chemicals, less fumes and dust, which means no clean up after work is performed

Minimal waste – laser cleaning does not leave collateral waste or leftover hazardous materials

Environmentally friendly – chemical cleaning materials are not required and any waste can be easily removed via a vacuum | Stop wasting time and money on pressure washing or sand blasting

With the removal of rust with laser cleaning, no great forces are used to remove the rust infection into the environment, but it’s also possible to clean large surfaces in a short period of time with very little labor and cost in comparison to traditional cleaning. For instance, you can fully strip a car down to the bare metal in only an hour. To remove rust with laser beams, a laser wand is aimed at the rust layer and slowly passes over the entire surface. The beam moves quickly back and forth and covers a width of 5 to 100 cm. Because of the short but highly focused laser pulses, the temperature of the rust layer quickly becomes very high.

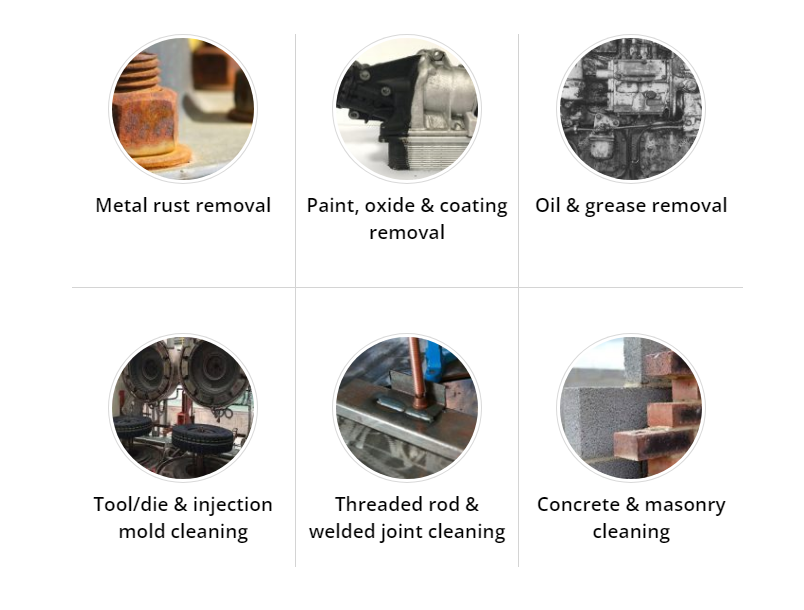

What can you clean with a laser?

Laser cleaning is a relatively new technology with a significant number of commercial and industrial applications –

this means a huge number of potential customers!

Some examples of what laser cleaning can do are the following:

Rust & Oxidation Removal

Rust is formed by the corrosion of iron; overtime rust will slowly damage underlying materials and can lead to part failure. Keeping your tools and equipment free from rust and oxidation will prolong their lifespan! Laser cleaning technology can be used for oxide removal and there is no need for chemicals, reducing environmental risk and impact. At AlienLaserCleaning.com we can clean everything from small machinery to large and complex rusted surfaces.

Common Laser Cleaning

Coating and rust removal

Laser cleaning removes coating and deposits including oil and rust.

Weld inspections

Laser cleaning leaves a fully exposed weld in clean condition, enabling NDT inspection without worry of residues impacting results.

Areas requiring precise work

When there is an area with sensitive equipment (i.e. electrical), laser is the best option.

Architectural cleaning

With laser cleaning we can restore statues, monuments, plaques, buildings, and structures without damaging the original surface.

Environmental sensitive areas

Laser cleaning is an eco-friendly option as all materials are collected in a vacuum system, making laser cleaning the best choice for areas where pollution and containments must be minimized (i.e. Waterways, Hospitals).

Laser Cleaning & Laser Machine FAQ (Texas)

Looking for mobile laser cleaning services in Texas or comparing laser cleaning machines? Here are the most common questions we get about laser rust removal, laser paint removal, and laser ablation.

What is laser cleaning?

How does laser cleaning work?

Is laser cleaning safe for metal?

Can laser cleaning remove rust completely?

Can laser cleaning remove paint, powder coat, or coatings?

Will laser cleaning damage the base material?

Does laser cleaning create heat or warping?

Is laser cleaning better than sandblasting?

Is laser cleaning eco-friendly?

What surfaces can you laser clean?

Can laser cleaning be done on-site (mobile) in Texas?

How much does laser cleaning cost?

How long does laser cleaning take?

What is the difference between pulsed laser cleaning and continuous-wave (CW) cleaning?

What size/power laser cleaning machine do I need (100W, 200W, 300W, 500W, 1000W, 2000W)?

Can a laser cleaning machine run on 110V or 220V?

What maintenance does a laser cleaning machine need?

Do you offer training for laser cleaning operators?

What safety gear is required for laser cleaning?

Can laser cleaning remove grease, oil, and soot?

Can you laser clean automotive parts, frames, or restoration projects?

Do you sell laser cleaning machines as well as provide services?

How do I get a laser cleaning quote in Texas?

Want a fast quote or machine recommendation?

Contact Alien Laser Cleaning for Texas mobile laser cleaning, laser rust removal, laser paint removal, and laser cleaning machines.

Locations:

Office Hours:

Monday – Friday

8:00 Am to 4:00 PM

*Closed Saturday & Sunday

Contact Us:

Phone: +1-254-300-6075

Email: alienlasercleaning@gmail.com

laser cleaning services, industrial laser cleaning, laser rust removal, laser paint removal, laser cleaning near me, mobile laser cleaning, laser cleaning business, laser cleaning equipment, laser cleaning cost, laser cleaning machine for hire, laser cleaning company, laser ablation cleaning, laser cleaning solutions, laser cleaning contractors, laser cleaning technology, laser cleaning machines